LRCM software modules

In developing the LRCM software we sought to solve specific maintenance information problems encountered by managers and engineers. Firstly we found that the RCM language and thinking process diminishes once the RCM project is over and time passes. Ambiguous EAM failure codes and catalog values selected by the technician from drop down lists on a work order are only an imperfect remnant of the rich RCM process that generated them. Secondly, technicians have few ways to formally recommend improvements to the RCM knowledge base. And thirdly, the catalog values diverge from reality so that work order recorded data is inconsistently recorded and often completely incorrect. All maintenance managers recognize the poor quality of their EAM work order history databases. This problem had to be solved before maintenance effectiveness can advance.

In developing the LRCM software we sought to solve specific maintenance information problems encountered by managers and engineers. Firstly we found that the RCM language and thinking process diminishes once the RCM project is over and time passes. Ambiguous EAM failure codes and catalog values selected by the technician from drop down lists on a work order are only an imperfect remnant of the rich RCM process that generated them. Secondly, technicians have few ways to formally recommend improvements to the RCM knowledge base. And thirdly, the catalog values diverge from reality so that work order recorded data is inconsistently recorded and often completely incorrect. All maintenance managers recognize the poor quality of their EAM work order history databases. This problem had to be solved before maintenance effectiveness can advance.

Main menu of Mesh LRCM

The opening menu of Mesh includes buttons for each module as well as a section recording a number of key performance indicators regarding the RCM knowledge in the database. Dashboards allow the users to dig deeply into these performance metrics.

The opening menu of Mesh includes buttons for each module as well as a section recording a number of key performance indicators regarding the RCM knowledge in the database. Dashboards allow the users to dig deeply into these performance metrics.

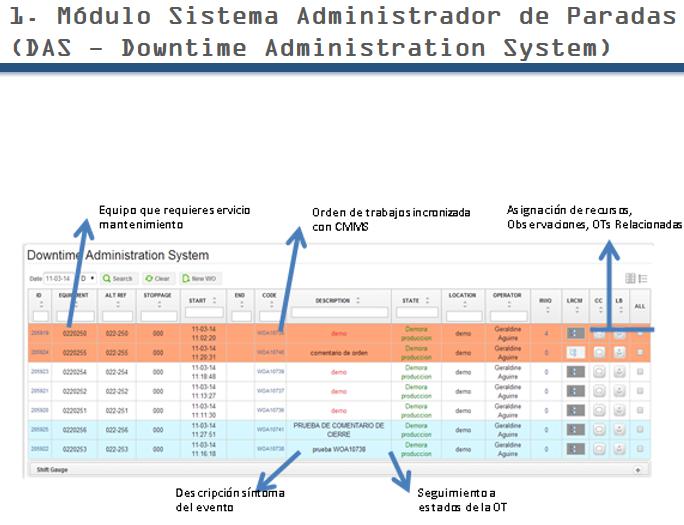

Downtime administration system (DAS)

This module provides instant access to any work order. This process is facilitated by an ample set of filters. It suffices to type a few characters in any header to quickly locate the work order of interest. This work order is the gateway to the LRCM module where the technician quickly and easily reports 100% accurate information required for eventual reliability analysis by the maintenance engineer.

This module provides instant access to any work order. This process is facilitated by an ample set of filters. It suffices to type a few characters in any header to quickly locate the work order of interest. This work order is the gateway to the LRCM module where the technician quickly and easily reports 100% accurate information required for eventual reliability analysis by the maintenance engineer.

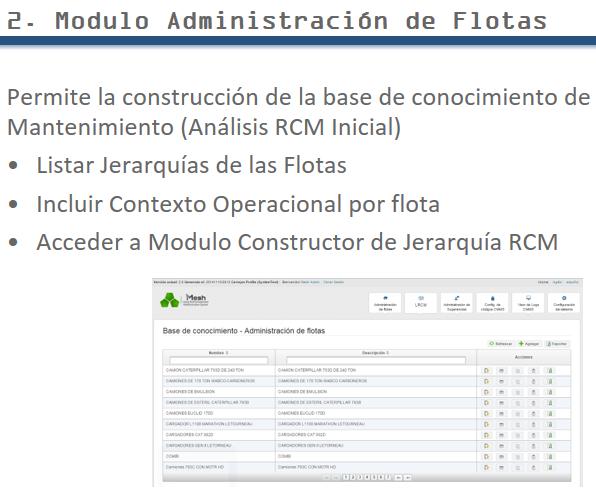

Fleet knowledge administration

Accessing the RCM analysis of an equipment type or fleet is accomplished, as in the DAS, by typing a few characters into any of the filter headers. From this page you can enter or copy and past rich text that describes the operating context upon which the RCM analysis is based.

Accessing the RCM analysis of an equipment type or fleet is accomplished, as in the DAS, by typing a few characters into any of the filter headers. From this page you can enter or copy and past rich text that describes the operating context upon which the RCM analysis is based.

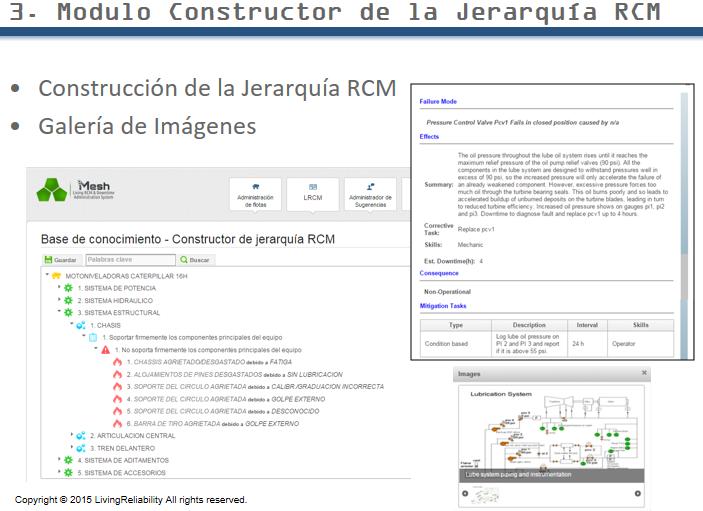

RCM knowledge builder module

RCM software should be as unobtrusive as possible so that it may be used to record and edit the results of a facilitated analysis in real time. Because Mesh is a multi user, multi tasking cloud application, the RCM analysis is instantly available to technicians, engineers and analysts. The RCM analysis should remain as an active and dynamic part of day to day maintenance long after the initial RCM project has terminated.

RCM software should be as unobtrusive as possible so that it may be used to record and edit the results of a facilitated analysis in real time. Because Mesh is a multi user, multi tasking cloud application, the RCM analysis is instantly available to technicians, engineers and analysts. The RCM analysis should remain as an active and dynamic part of day to day maintenance long after the initial RCM project has terminated.

This module is the MESH RCM knowledge repository. Among its many innovations is the ability to embed images into the failure mode and effects description fields. This feature was added primarily to allow the maintenance organization to clearly define what “failure” means within the context of each failure mode. When the failure versus suspension decision is not clear the image capability will allow organizational standards to evolve through discussion and consensus.

Knowledge Builder also includes a configurable criticality (risk) matrix associated with each failure mode as well as other features designed to support accurate work order reporting.

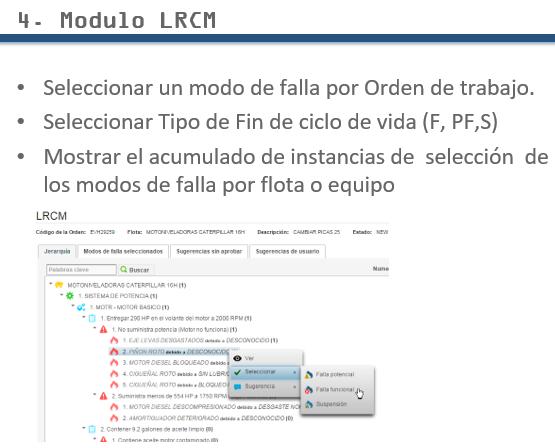

LRCM module – failure mode selection

The work order data entry (LRCM) module is the central innovation of MESH LRCM. For the first time maintenance and reliability engineers can be confident that analyzable grade data will be returned via the work order to the EAM. The MESH work order data entry interface provides two key functions:

The work order data entry (LRCM) module is the central innovation of MESH LRCM. For the first time maintenance and reliability engineers can be confident that analyzable grade data will be returned via the work order to the EAM. The MESH work order data entry interface provides two key functions:

- The ability to select the failure mode and its event type (failure, potential failure, and suspension) directly from the RCM tree view of the knowledge base.

- The ability to assess and feed back, dynamically, any discrepancy between the RCM knowledge and observed reality regarding the failure modes, their effects, consequences and mitigating tasks.

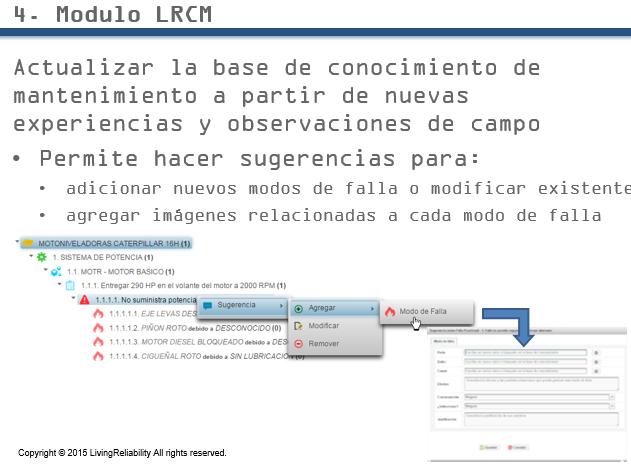

LRCM module – knowledge feedback

Gaps easily develop between the initial RCM knowledge base as reflected in the EAM failure catalog values and reality as it is observed day-to-day by technicians troubleshooting and executing work order tasks. Technicians must have a way to report such divergences and suggestion how to correct or refine the knowledge base. Slide 22 illustrates the MESH feedback function.

Gaps easily develop between the initial RCM knowledge base as reflected in the EAM failure catalog values and reality as it is observed day-to-day by technicians troubleshooting and executing work order tasks. Technicians must have a way to report such divergences and suggestion how to correct or refine the knowledge base. Slide 22 illustrates the MESH feedback function.

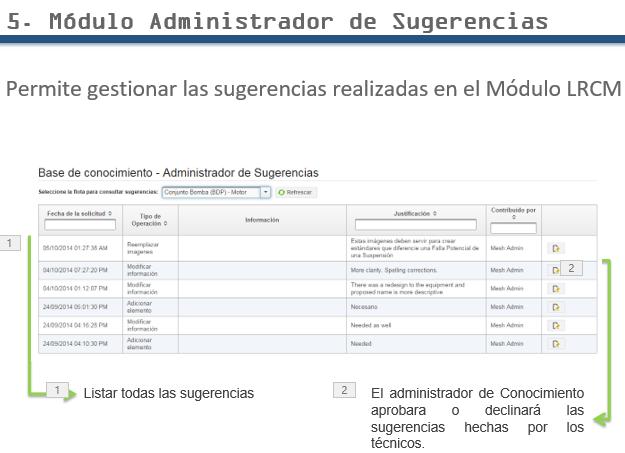

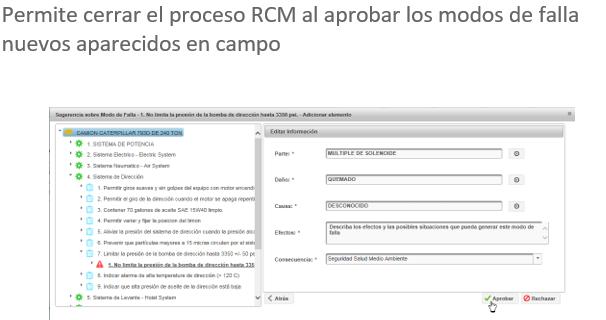

Knowledge feedback administration

The RCM knowledge base is a valuable intellectual asset. It’s function is to represent the collective knowledge justifying the current maintenance plan. Knowledge, by definition, is imperfect, incomplete, or inaccurate and must be continuously improved in order that it may fulfill its role.

The RCM knowledge base is a valuable intellectual asset. It’s function is to represent the collective knowledge justifying the current maintenance plan. Knowledge, by definition, is imperfect, incomplete, or inaccurate and must be continuously improved in order that it may fulfill its role.

The Feedback Manager interface allows the reliability engineer responsible for maintaining the RCM knowledge base to assess, acknowledge, edit, accept or reject suggestions by the technician fed back through the LRCM work order module.

The Feedback Manager interface allows the reliability engineer responsible for maintaining the RCM knowledge base to assess, acknowledge, edit, accept or reject suggestions by the technician fed back through the LRCM work order module.

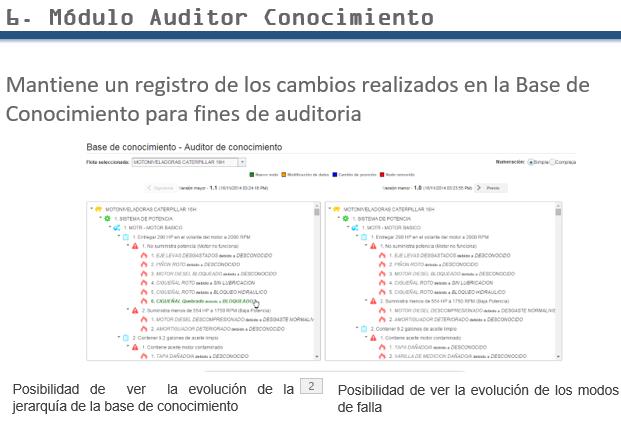

Knowledge trail module

When serious failure strikes, especially one whose consequences are health, safety, or environmentally (HSE) related we need to discover what went wrong on our maintenance plan. What did we know about the failure mode and when did we know it? What compensating provisions or mitigating tasks were in place? Were they adequate. MESH can scroll backward and forward in time and display the state of knowledge any previous point, so as to determine whether the failure mode was well understood, its consequences mitigate, and what further should be done.

When serious failure strikes, especially one whose consequences are health, safety, or environmentally (HSE) related we need to discover what went wrong on our maintenance plan. What did we know about the failure mode and when did we know it? What compensating provisions or mitigating tasks were in place? Were they adequate. MESH can scroll backward and forward in time and display the state of knowledge any previous point, so as to determine whether the failure mode was well understood, its consequences mitigate, and what further should be done.

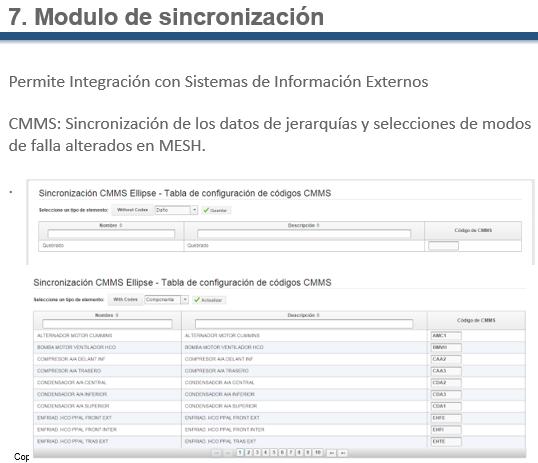

RCM knowledge EAM code catalog synchronization module

As new and updated knowledge elements accrue in the RCM knowledge base, it is essential that the catalog values continue to reflect reality and the latest understanding of failure behavior. Otherwise reliability analysis will fail to keep pace with the moving target that maintenance tends to be. Periodically, the reliability analyst should run the synchronization to determine what updates should be made in the EAM failure catalogs.

As new and updated knowledge elements accrue in the RCM knowledge base, it is essential that the catalog values continue to reflect reality and the latest understanding of failure behavior. Otherwise reliability analysis will fail to keep pace with the moving target that maintenance tends to be. Periodically, the reliability analyst should run the synchronization to determine what updates should be made in the EAM failure catalogs.

Analysis and reporting module

Our evolving understanding, as we explore and implement LRCM principles, points increasingly to the need to track and examine the low level (leading) KPIs. These would include numbers such as the rate of day-to-day growth of RCM knowledge, the quantity of samples generated and number of analyses performed, number of comments and RCM update recommendations received from the field, and so on. In other words, the indices over which we have direct control.

We will find the golden fleece one day soon. That will be when we, as managers and engineers, can look at the low and high level indicators simultaneously and understand the complex relationships between them. Then management will be better placed to do its job, which is to inject maintenance energy optimally into those activities that they know will increase profitability.

© 2017 – 2021, Murray Wiseman. All rights reserved.