One might imagine that we can obtain practical improvement in maintenance performance quickly and inexpensively by concentrating on CBM technology for example, Oil Analysis.

The supposition is reasonable but overlooks an obstacle that impedes verifiable and optimal CBM decision making in most maintenance organizations. In order to apply CBM we must have identified a condition indicator and a value of that indicator that signals that a component is in potential failure state. The problem is the maintenance engineer’s inability to define, for a failure mode of interest, the relevant condition indicator and a level that signals its potential failure.

Although reliability analysis (RA) methods exist for determining the relationship between CBM data and failure probability age data needed by RA software applications is inadequate. By “age data” we mean a historical record of the life ending events of specific parts and failure modes. The enterprise asset management (EAM) system can acquire and generate the needed data samples. However, the age data transferred to the EAM from the technicians’ observations via work orders is inadequate because, by-in-large, it is inconsistent, incomplete, or incorrect. This long standing problem can be easily solved by using EXAKT and LRCM.

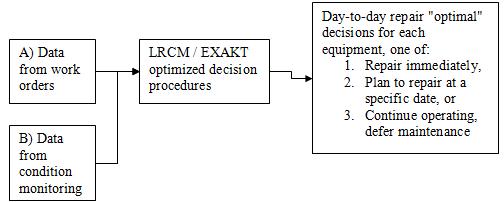

Two key maintenance decision making information sources are:

- Age data from work orders, and

- Condition data from condition monitoring activities,

as illustrated below:

The flow diagram illustrates that maintenance decisions reduce to one of three choices: to renew a component immediately, to schedule renewal it at a specified time, or to defer the decision until the next observation. We would suspect that the optimal decision might be driven by data from sources A and B. The effectiveness of the maintenance department will depend on making the correct choices, repetitively, day to day, over the long run. The problem then is to find a practical method to convert overwhelming volumes of data into optimal maintenance decisions.

The flow diagram illustrates that maintenance decisions reduce to one of three choices: to renew a component immediately, to schedule renewal it at a specified time, or to defer the decision until the next observation. We would suspect that the optimal decision might be driven by data from sources A and B. The effectiveness of the maintenance department will depend on making the correct choices, repetitively, day to day, over the long run. The problem then is to find a practical method to convert overwhelming volumes of data into optimal maintenance decisions.

An optimal decision process, by definition, is one that can be traced to business profitability. LRCM is a process for ensuring analyzable data. EXAKT is an advanced form of Reliability Analysis (RA) that converts data sources A and B into verifiable optimal model generated decisions.

A LRCM / EXAKT implementation project begins by ensuring quality in Data Source A. Data source B, CBM data, is generally already well structured, consistent, and accurate. Data source A, however, is usually inconsistent, incomplete, and inaccurately recorded into the EAM. Once LRCM has implemented the processes needed for good age data, the success of the CBM initiative will depend solely on whether the monitored condition data actually contains predictive capability. The EXAKT software will not only make this determination but will determine which extracted features from the data are significant risk factors. Furthermore, the software will deploy a model that will combine failure probability and relevant business factors to recommend the optimal moment for CBM intervention. This is an automated predictive process whose performance is measured within the optimal decision process itself. Finally the EXAKT predictive agent issues, upon processing the current set of CBM data, a Remaining Useful Life Estimate (RULE) and a confidence interval.

For this desirable CBM decision process to occur in the maintenance environment Data Source A must have attained the required level of quality. LRCM procedures ensure age data of the requisite analyzable quality. LRCM accomplishes this by discriminating between recorded instances of Failure and “Suspension” [1]. These failure mode life ending events, combined with CBM data, are both necessary and sufficient conditions of an effective and verifiable maintenance decision process.

© 2013 – 2015, Murray Wiseman. All rights reserved.

- [1]A suspension is the discretionary renewal of a part that has not failed. The lack of a process in most maintenance departments for the accurate discrimination in the EAM between Failure and Suspension has obstructed the application of RA and optimal decision models.↩