Living RCM Certified® [1] procedures for work order data entry allow reliability engineers to perform reliability analysis [2]. Analysis usually precedes improvement. Living RCM Certified® adheres to the RCM terminology set in Standard SAE JA1011. Standard ISO 14224 uses a different set of terms derived from FMECA (Mil Std 1629A). Maintenance engineers analyzing and reporting data from the EAM and CBM systems tend to use terminology from both standards. Clashes in the meanings of terms can lead to misunderstandings when performing reliability analysis.

Identical words and phrases will differ in meaning depending on which lexicon (ISO 14224 or SAE JA1011) governs a discussion. The terminology differences can be confusing. If we wish to apply reliability analysis to data samples from the EAM system, we should be aware of those differences. We can consult a table that maps their respective terms between the two standards. Such a table follows:

| Term | ISO 14224 | RCM (SAE JA1011) |

| Failure mode | effect by which a failure is observed on the failed item | The event that causes the failure. Its taxonomy has three levels: 1. Object part 2. Object damage (failure mechanism) 3. Failure cause. These can be expressed in a sentence arranged as noun, action phrase, and due-to clause. |

| Failure | termination of the ability of an item to perform a required function | Same meaning as ISO 14224 except that RCM makes a point of recognizing both total and partial termination since total and partial failures will usually be caused by different failure modes and will engender differing effects, consequences, and mitigating actions. |

| Failure mechanism | physical, chemical or other process that leads to a failure | Same meaning as ISO 14224 except that the failure mechanism is included as the second element (object damage) of the failure mode. |

| Failure cause | circumstances associated with design, manufacture, installation, use and maintenance that have led to a failure | Same meaning as ISO 14224 except that the failure cause is included as the third element of the failure mode. |

| Failure effects | Not defined explicitly in the ISO standard. However the term “effect” is used (in Table 6 — Failure data) to mean impact on equipment function. | A textual narrative of the sequence of pertinent events that take place before, during, and subsequent to the failure mode event. The events described include those that occur within the object part, component, subsystem, system, equipment, organization, community, and world depending on the severity of the consequences of failure. |

| Failure consequences | Not explicitly defined in the the ISO standard. However the term is used in Note b of Table 6 – Failure data, “Failure impact on plant operations. “Failure consequence” is also used in Appendix C, table “C.1 Failure consequence classification” (p 140) as a factor in risk analysis. | The reason why the failure matters, one of: 1. Hidden 2. Health, Safety, Environment (HSE) 3. Operational 4. Non-operational Each is the starting node of a branch in the RCM decision tree leading to a failure mitigation policy targeting the failure mode under consideration. |

Conclusion

RCM definitions of the maintenance knowledge elements are concise, unambiguous and can be more easily applied than those of ISO 14224. This is important because reliability analysis counts, in a variety of ways, the number of instances of a failure mode in a sample of maintenance events. The ratio of the sum of life spans ending in failure to the count of failure mode instances approximates[3] the MTTF. Weibull analysis goes further by relating the probability of failure to age. Extended Weibull analysis[4] includes the influence of CBM condition indicators in the probability calculation. All forms of reliability analysis require a sample from the EAM (work order) database. Failure mode instances must be identified consistently in the database for purposes of analysis.

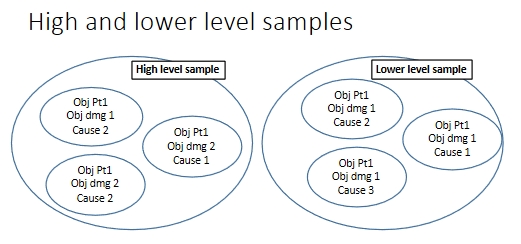

Two examples: Higher level sample includes 3 instances of failures of Obj Part 1 regardless of mechanism (obj dmg) and cause. Lower level sample contains 3 instances of failures of Obj Part 1 by mechanism “Obj dmg 1” but including multiple causes.

RCM’s failure mode definition is particularly convenient for reliability analysis because it packages, hierarchically, the object part, object damage, and failure cause. Should only a high level analysis be required (see diagram) or should the sample be small, we could filter failure mode instances only to the level of the object part. This high level of analysis is often appropriate for reliability improvement activities. Should the availability or reliability needs in a given context require it, we could query failure mode instances having specific failure mechanisms and / or failure causes, provided we have a large enough sample. Hence it is usually preferable to identify object parts at a higher level and include additional detail (when relevant) in the failure mechanism and cause segments of the failure mode. By keeping the needs of reliability analysis in mind the level of detail and depth in a given branch of the RCM knowledge hierarchy will continually self-adjust as a result of daily interaction between the technician, reliability engineer, and the maintenance information system.

© 2016 – 2020, Murray Wiseman. All rights reserved.

- [1]A maintenance work order related methodology to ensure analytic grade age data in the EAM database and continuous updating of the RCM knowledge base. These are the prerequisites for model based maintenance decisions.↩

- [2]Reliability analysis is the conversion of age and condition data to decision enabling rules called “models”↩

- [3]The ratio does not consider life suspensions due to PM or lifetimes having their life beginnings or endings outside the sample.↩

- [4] called Proportional Hazard modeling (PHM)↩

Comment from Eric:

I feel your table does a good job at laying out the terms and making the differences in definitions clear. As explained in your table, the definition of Failure Mode has the greatest variance in meaning. SAP PM can be utilized to support either definition but it would require different configuration. The out of the box fields in SAP align with the ISO definitions and the failure codes specific to create catalogues within the Object Part, Damage and Cause fields.

Capturing the Object Part, Damage and Cause as separate data fields requires a roll up of the 3 to constitute a failure mode as defined by RCM.

With regards to the Failure term, SAP provides a breakdown indicator field which is suggested by some to differentiate between Partial and Total failure, but this is outside of ISO and falls back on the company to provide the definition of the intended use of this function.

Comment from Hossein:

That is an interesting article indeed. I can remember when we started converting FMEA documents to RCM we experienced such confusion when the “Failure mode” in FMEA was equivalent to “Effect” in RCM.