Most large maintenance organizations have a history of pursuit of excellence on the cutting edge of maintenance management. They are avid consumers of maintenance technology, their staff read maintenance related magazines, and they attempt to implement most of the new ideas that they find there. These often include: Condition monitoring, design for reliability and maintainability, hazard studies, expert systems, computerized maintenance management systems, failure modes and effects analysis, participation, flexibility, multiskilling, teamwork, RCM, ISO 55000 and so on. The desire and will to improve is alive and strong in all maintenance departments.

In particular, these organizations have recognized for years the potential of Condition Based Maintenance (CBM) as a way to increase reliability and availability while reducing costs. Some of them have set up their own oil analysis laboratories as well as vibration analysis programs and related initiatives. CBM data are meticulously organized in databases and in certain cases are incorporated into the CMMS/EAM.

Having reached this point, they arrive at the ultimate challenge. How can the maintenance organization use CBM data together with the record of actual failure events as recorded in their EAM to improve maintenance performance, and measurably so? It is reasonable to consider that historical CBM data combined with coincident failure data hold the key to predictive capability. With both data sources one should be able to:

- evaluate the ability of current CBM activities to predict failure, and

- improve the interpretation and predictive capability of CBM data.

It turns out that the mathematics of developing optimized CBM decision models from CBM and failure age data are well understood and well tested. Software (e.g. EXAKT) has been used for this purpose for several years. Such software provides a remaining useful life estimate (RULE) with stated confidence by processing the latest CBM data. At the same time it issues an “optimal” recommendation based on business factors (consideration of costs, safety, and equipment availability).

A CBM prediction method using advanced reliability analysis is, therefore, not lacking. The problem that maintenance managers need to address is more basic. The EAM plays a key role in resolving it. The obstacle, as one can well imagine, centers around data. The solution lies in the ability of the EAM to feed the “correct” data to the reliability analysis process.

Reliability Analysis (RA) needs a particular type of data. That data is sometimes referred to as “Age” or “Life” data. It consists of the following information:

- The failure mode that has occurred, and

- The Event Type, specifically, whether the failure mode life ended by Functional Failure, Potential Failure, or by Suspension.

A “potential failure” is a failure that has been caught just in time before more serious consequences would have occurred. A “suspension” is a renewal of a failure mode for reasons other than failure. Reliability analysis requires (see Defeating CBM) that the distinction be made in the field, and in the EAM, between instances of Failure and Suspension. This will require an understanding of certain RCM principles by technicians and supervisors involved in the work order process. An organization may easily embark on LRCM. During ramp up, they will adopt a new perspective when reporting “as-found equipment condition” on the work order. An LRCM pilot should address the most troublesome equipment whose reliability is critical for production.

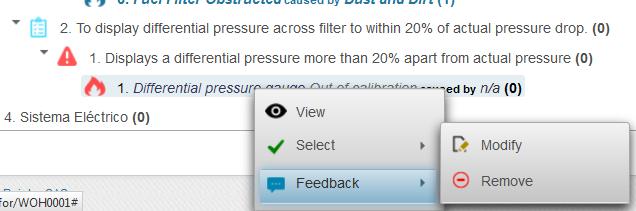

A major function of LRCM concerns the the management of the relationship between the work order system (EAM) and the RCM knowledge base. In the LRCM process a reliability engineer continuously refines the RCM knowledge base. He accomplishes this by means of a knowledge feedback system incorporated directly in the work order. The advantage is obvious.

With the details of the work order fresh in mind, the technician can conveniently recommend an update to the RCM knowledge base. The RCM facilitator uses a feedback management tool to edit, authorize, and implement the suggestion. With this novel dynamic RCM style of information management, the EAM will generate, routinely, the required “samples” of life data required for analysis and decision model generation. A sample is a collection of failure mode life cycles each defined by their beginning and ending events. Reliability analysis can proceed only upon the availability of unbiased, well structured data samples. LRCM is a human-oriented process by which we ensure that such samples are systematically available for analysis and continuous improvement.

© 2011 – 2015, Murray Wiseman. All rights reserved.