Quick video

BACKGROUND

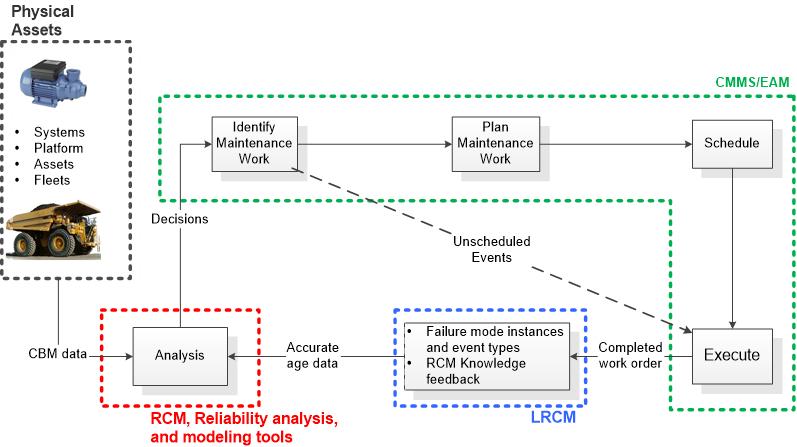

As one of their principal functions work order and condition monitoring systems provide data to the reliability engineers in a maintenance organization. Why collect data? To support decisions regarding what maintenance to perform, where, and when. An “optimal” decision rule or policy will apply the right maintenance at the right time to the right components in a way to achieve highest long term profitability. Maintenance managers and engineers have long believed that within their data lie the secrets to achieving optimal decisions. That realization has driven the growth of high technology services and tools to collect, display, manipulate, store, and analyze limitless quantities of data.

THE PROBLEM

Given that the amount of data available is infinite, the maintenance engineer faces new questions:

- Which data will support optimal decision making? and

- How should one transform the relevant data into optimal maintenance policies? and

- How should one verify the performance of those policies in order to improve them continuously?

THE Living RCM Certified® SOLUTION

The “Living” Reliability Centered Maintenance methodology addresses three challenges to Achieving Reliability from Data:

- Management of the relationship between the work order system and the maintenance knowledge base,

- Sample generation, and

- Reliability analysis.

Living RCM Certified applies fundamental Reliabability Centered Maintenance (RCM) thinking to each challenge by combining technology solutions that encourage vital human participation and control over the entire process. Key information needed from the CMMS/EAM is “age” or “life” or “event” data. Simply, Living RCM Certified® enables the referencing and growth of knowledge. Each significant work order becomes both an instance of a Failure Mode and a point in a sample essential for conducting a Reliability Analysis and developing practical, verifiable day-to-day work selection decision models that optimize maintenance activities.

Living RCM Certified applies fundamental Reliabability Centered Maintenance (RCM) thinking to each challenge by combining technology solutions that encourage vital human participation and control over the entire process. Key information needed from the CMMS/EAM is “age” or “life” or “event” data. Simply, Living RCM Certified® enables the referencing and growth of knowledge. Each significant work order becomes both an instance of a Failure Mode and a point in a sample essential for conducting a Reliability Analysis and developing practical, verifiable day-to-day work selection decision models that optimize maintenance activities.